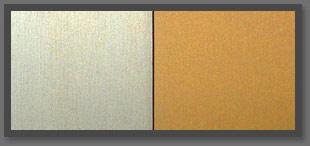

Hexavalent / Trivalent chromate

CHROMATE TREATMENT

Chromate treatment is a surface treatment that makes it possible to lay down an inorganic and amorphous layer of a thickness that varies between 0.01 and 3 micrometres. The setting of the layer is done in an aqueous solution that contains hexavalent or trivalent chromate ions (according to the treatment done).

This treatment protects against corrosion and can also be used to increase adhesion for other types of surface treatment, such as painting. There are two types of treatments offered at Anodisation Québec: the trivalent chromate treatment (ROHS) and the hexavalent treatment (Iridite 14-2).

The MIL-DTL-5541F standard serves to identify and separate the resistance to corrosion into 2 different types: the hexavalent chromate treatments (type 1) and the others (type 2). This standard must be verified in order to confirm the presence of the treatment performed on one part. To be in compliance with the standard, a part having underwent a treatment must be able to withstand 336 hours of exposure to a saline fog. Through this method, the treatment would be certified class 1A.

TRIVALENT TREATMENT

The trivalent chromate is a treatment that does not affect the part's colour. Corrosion resistance will also be increased. According to the literature, the trivalent chromate (ROHS) is as performing as the hexavalent chromate. It would this be in compliance with the type 2 class 1A standard.

HEXAVALENT TREATMENT (IRIDITE)

With regard to hexavalent treatment (Iridite), the colour obtained is a dark yellow that varies according to the time of immersion in the treatment basin. According to the MIL-DTL-5541F standard, this treatment is a part of type 1. The class 1A certification has been obtained for this treatment.